Engineering • Fabrication • Prototyping

Valence Innovation is a Redford, MI based engineering and manufacturing and industrial services supplier specializing in practical, efficient solutions for complex fabrication challenges and repairs. We support projects from concept through production with a focus on speed, clarity, and real-world manufacturability.

Capabilities

- Engineering & Design

- CAD modeling, product development, reverse engineering

- Design for laser cutting, press brake forming, welding, and CNC machining

- Fabrication & Manufacturing

- CNC and manual machining

- Welding (MIG/TIG) fabrication

- Custom fixtures, jigs, and tooling

- Prototyping & One-Off Builds

- Proof-of-concept models

- Low-volume production

- Rapid problem solving for unusual or difficult parts

- Heavy Equipment Repair & Modification

- Custom attachments

- Machine rebuilds, industrial retrofits

Industries Served

- Automotive & transportation

- Industrial equipment & manufacturing

- Energy, Oil/Gas

- Agricultural

- Construction & trades

- Architecture, interiors, and custom metalwork

- Art, sculpture, and public installations

Why Work With Us

- Practical engineering grounded in real shop capabilities

- Fast turnaround and clear communication

- Ability to prototype, iterate, and manufacture in-house

- Experience with unusual, custom, or “one-off” challenges

- Trusted by startups, builders, industrial clients, and creatives

Contact

Valence Innovation

Redford, Michigan

Email: davidrvalencia@gmail.com

Phone: 248-345-3972

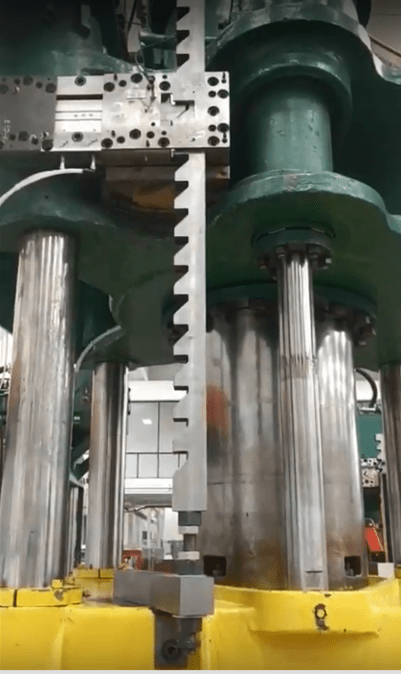

Project Example

Below is an image of a ratcheting press safety system that Valence Innovation recently designed. Large components were made by the customer and the smaller components were made by Valence. This system was installed 3 separate hydraulic presses (6 units, 2 per press). Its purpose is to stop the cylinder from drifting more than 3″ when the press is not being actively controlled by the operator. This adds an additional level of safety to the operator in the event of a mechanical or hydraulic failure.